- This topic is empty.

-

AuthorPosts

-

2025-09-03 at 4:25 pm #4662

In today’s competitive manufacturing landscape, precision, efficiency, and reliability are critical for producing high-quality gears. Whether it’s for automotive components, industrial machinery, or precision equipment, CNC profile gear grinding machines have become essential tools for modern manufacturing facilities. These machines deliver unparalleled accuracy, repeatability, and surface quality, ensuring that gears meet stringent industry standards.

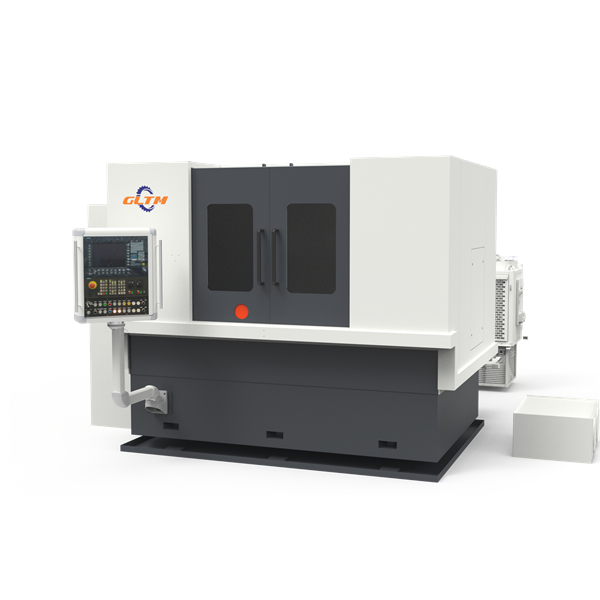

GLT Machinery (GLTM/GLT), a leading Chinese manufacturer of high-speed, high-efficiency CNC gear hobbing machines, focuses on delivering solutions with high rigidity, efficiency, and reliability. Their machines serve industries including automotive, motorcycles, reducers, synchronous pulleys, and pumps, providing comprehensive gear production solutions to clients worldwide.

In this article, we’ll explore the top 7 benefits of using a CNC profile gear grinding machine in modern manufacturing.

1. Exceptional Precision and Accuracy

CNC profile gear grinding machines are designed to achieve high-precision gear profiles with tight tolerances. Unlike traditional gear cutting methods, these machines allow for precise control over tooth geometry, pitch, and surface finish.

This precision is essential for applications like automotive transmissions, industrial reducers, and high-performance machinery where even slight deviations can lead to performance loss or premature wear. GLT Machinery’s CNC solutions are engineered to maintain consistent accuracy across large production batches.

2. Improved Surface Quality

Surface finish plays a vital role in gear efficiency and noise reduction. CNC gear grinding produces smooth, finely finished surfaces that reduce friction, minimize wear, and extend gear life.

Using high-quality CNC machines from GLT ensures uniform surface texture, which is crucial for high-speed and heavy-load applications, including pumps, synchronous pulleys, and precision motor components.

3. High Production Efficiency

CNC profile gear grinding machines are optimized for high-speed and efficient operations. Advanced control systems and automation allow manufacturers to reduce cycle times without compromising accuracy or quality.

GLT Machinery focuses on high-efficiency design principles, enabling industries to scale production while maintaining consistency. This translates into faster turnaround times and reduced operational costs.

4. Versatility in Gear Types

Modern manufacturing often requires flexibility to produce a variety of gear types. CNC profile gear grinding machines can handle:

-

Spur gears

-

Helical gears

-

Worm gears

-

Synchronous pulleys

-

Specialized custom gears

This versatility allows manufacturers to meet diverse client needs without investing in multiple specialized machines. GLT Machinery provides adaptable solutions to cover various industries and gear specifications.

5. Reduced Risk of Errors

Manual gear grinding and hobbing methods are prone to human error, which can lead to defective products and material waste. CNC systems offer automated control and precise programming, drastically reducing the risk of errors.

GLT Machinery integrates robust control systems into their CNC gear grinders, ensuring consistent quality, repeatability, and reliability across production batches.

6. Long-Term Cost Savings

Although CNC profile gear grinding machines represent a higher initial investment, they provide significant long-term cost benefits. Reduced scrap rates, lower maintenance, and increased productivity contribute to lower overall manufacturing costs.

By using GLT’s high-rigidity and high-reliability machines, manufacturers can enjoy durable equipment with minimal downtime, making the investment highly cost-effective over the machine’s lifespan.

7. Enhanced Compatibility with Industry 4.0

Modern manufacturing emphasizes smart production, digital monitoring, and process optimization. CNC profile gear grinding machines can integrate with Industry 4.0 systems, enabling real-time monitoring, predictive maintenance, and data-driven process improvements.

GLT Machinery’s CNC gear grinders are designed for easy integration with digital production lines, helping manufacturers achieve intelligent, automated, and highly efficient operations.

Conclusion

The adoption of CNC profile gear grinding machines brings numerous advantages to modern manufacturing, including exceptional precision, improved surface quality, high efficiency, versatility, error reduction, cost savings, and Industry 4.0 compatibility.

GLT Machinery (GLTM/GLT) stands out as a trusted provider of high-speed, high-efficiency CNC gear hobbing and grinding machines. With a focus on high rigidity, reliability, and efficiency, GLT delivers gear production solutions for automotive, motorcycle, reducer, synchronous pulley, and pump industries.

By integrating CNC profile gear grinding technology into your manufacturing process, you can enhance product quality, streamline operations, and stay competitive in today’s demanding industrial landscape.

http://www.gltmachinery.com

Wuxi General Machinery Co., Ltd. (GLTM / GLT) -

-

AuthorPosts

- You must be logged in to reply to this topic.