- This topic is empty.

-

AuthorPosts

-

2025-09-03 at 4:26 pm #4671

In modern manufacturing and mechanical systems, timing belt pulleys play a critical role in ensuring precise power transmission, synchronization, and efficiency. Whether used in packaging machinery, textile equipment, automotive systems, or industrial automation, choosing the right pulley can significantly impact performance, durability, and maintenance costs.

With numerous options available in the market, businesses often face challenges in selecting the most suitable pulley for their applications. This guide provides a comprehensive overview of how to choose the right industry timing belt pulley and highlights the expertise of Hetuoda Machinery Manufacturing, a professional manufacturer specializing in high-precision transmission components.

1. Understanding the Role of Timing Belt Pulleys

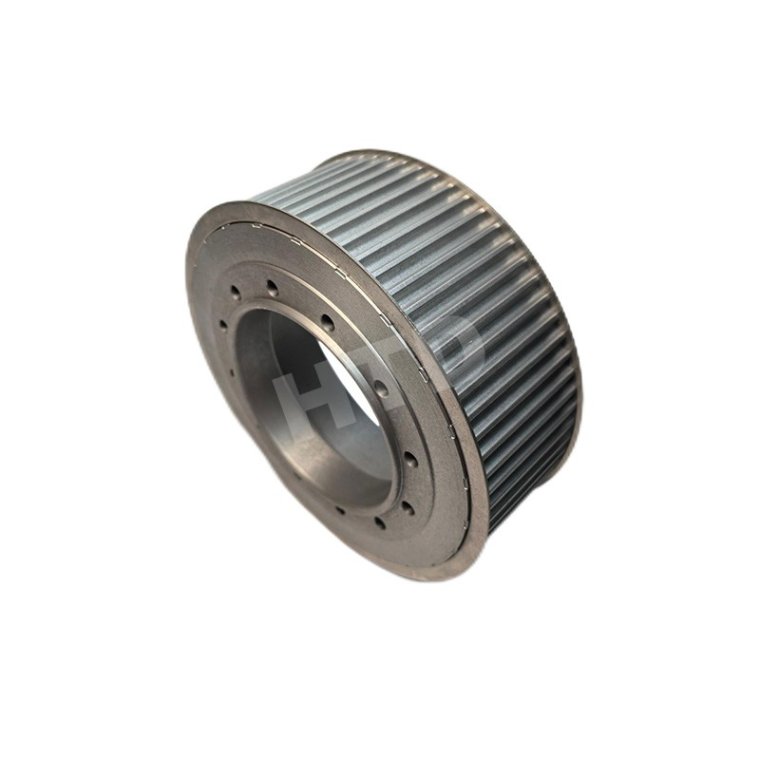

A timing belt pulley is a specialized wheel with teeth designed to mesh with a timing belt. Together, they ensure accurate rotation, eliminate slippage, and provide synchronized transmission of mechanical power. This makes them essential in industries where precision and efficiency are critical.

Common applications include:

-

CNC machinery

-

Textile and printing machines

-

Packaging equipment

-

Conveyor systems

-

Automotive engines and industrial automation

Hetuoda Machinery Manufacturing has extensive experience in designing pulleys that meet the needs of these diverse industries.

2. Key Factors to Consider When Choosing a Timing Belt Pulley

a) Material Selection

The choice of material affects the pulley’s strength, weight, and durability. Common materials include:

-

Aluminum: Lightweight and corrosion-resistant, ideal for high-speed applications.

-

Steel: Strong and durable, suitable for heavy-duty machinery.

-

Engineering Plastics: Lightweight and cost-effective, best for lighter applications.

Hetuoda provides pulleys in multiple materials, ensuring the right balance between performance and cost.

b) Tooth Profile and Pitch

The tooth profile determines how well the pulley meshes with the belt. Popular profiles include trapezoidal, HTD (High Torque Drive), and GT series. The pitch (distance between teeth) must match the belt to ensure smooth operation.

c) Size and Dimensions

Pulley size directly affects torque transmission, speed ratio, and system design. Choosing the correct bore size, diameter, and number of teeth is crucial for optimal performance.

d) Load Capacity and Application Requirements

For heavy-duty machinery, pulleys must withstand high torque and continuous operation. In contrast, lightweight applications may prioritize reduced inertia and lower noise.

e) Customization Options

Standard pulleys may not always meet unique industrial requirements. A manufacturer offering OEM services can design customized pulleys to match specific applications. Hetuoda specializes in OEM production, delivering tailored solutions to global clients.

3. Advantages of Working with a Professional Manufacturer

Partnering with an experienced manufacturer ensures consistent quality, precision, and long-term reliability. Hetuoda Machinery Manufacturing offers:

-

High-precision transmission parts: Timing belt pulleys, gears, tensioners, and more.

-

OEM and custom solutions: Designed for client-specific machinery.

-

Strict quality control: Ensuring compliance with international standards.

-

Wide industry applications: From textiles and packaging to automotive and aerospace.

4. Common Mistakes to Avoid

When selecting a timing belt pulley, avoid these common mistakes:

-

Choosing mismatched belt and pulley profiles

-

Overlooking load capacity requirements

-

Ignoring material suitability for the working environment

-

Neglecting supplier experience and after-sales support

By working with a trusted company like Hetuoda, businesses can avoid these pitfalls and ensure smooth, efficient operations.

5. Future Trends in Timing Belt Pulley Design

As industries move toward automation and high-precision manufacturing, the demand for lightweight, durable, and high-efficiency pulleys continues to grow. Smart materials, surface treatments, and CNC precision machining are shaping the future of pulley technology. Hetuoda stays ahead of these trends with continuous innovation and advanced production capabilities.

Conclusion

Selecting the right industry timing belt pulley is crucial for achieving efficient, reliable, and long-lasting performance in industrial applications. By considering factors such as material, tooth profile, size, and load capacity, businesses can optimize their machinery and reduce downtime.

With expertise in high-precision transmission components and a strong commitment to quality, Hetuoda Machinery Manufacturing provides businesses with durable timing belt pulleys, gears, tensioners, and customized OEM solutions. Trusted across industries like packaging, textiles, automotive, and aerospace, Hetuoda has become a reliable partner for global clients seeking superior transmission components.

If your business is looking for a dependable supplier of timing belt pulleys, Hetuoda Machinery Manufacturing offers the expertise, customization, and service you need to ensure long-term success.

http://www.cdepulley.com

Suzhou Hetuoda Machinery Manufacturing Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.