- This topic is empty.

-

AuthorPosts

-

2026-01-21 at 11:33 am #6282

In semiconductor packaging, reliability and yield are no longer determined only by design rules or equipment precision. As chip dimensions shrink and interconnect density increases, chemical cleanliness at the micro-scale has become a decisive factor. Among various contamination risks, organic residues introduced during bonding wire coating and plating processes are particularly critical. As a result, total organic carbon monitoring is gradually moving from a background laboratory task to a front-line quality control strategy. A well-configured toc total organic carbon analyzer now plays a direct role in yield protection and long-term device reliability. In this blog post, METASH, as high performance lab TOC analyzers manufacturer, will share information on the use of TOC Total Organic Carbon analyzers in chip packaging yield control.

Organic Carbon as a Yield-Sensitive Variable in Wire Bond Packaging

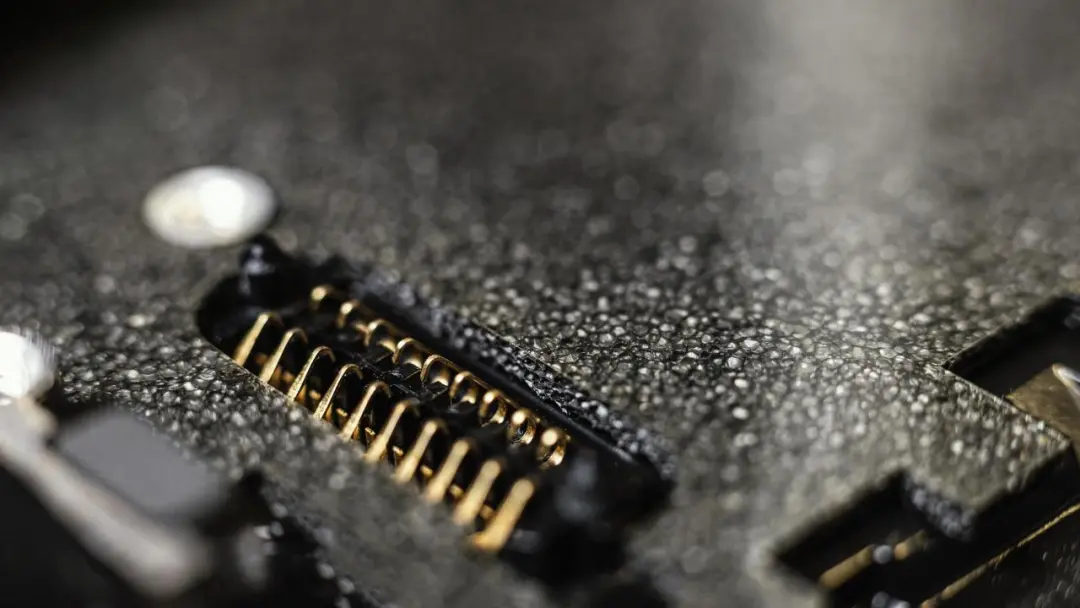

Bonding wires made from gold, copper, silver, or alloy materials form the final electrical path between the silicon die and the external leads. To meet higher performance and reliability requirements, many bonding wires are surface-coated or chemically treated to enhance corrosion resistance, oxidation control, and bonding stability.

These surface treatments are highly sensitive to organic contamination. Organic compounds introduced through plating additives, surfactants, stabilizers, or solvent residues may remain in coating solutions or adhere to the wire surface. Even at low concentrations, these contaminants can disrupt coating formation and interfacial bonding behavior. Typical risks include uneven film thickness, weak adhesion between coating and substrate, and hidden defects at the bond interface. Such issues often escape early inspection and only emerge during thermal cycling or humidity stress tests, directly impacting final yield.

Why TOC Is More Effective Than Conventional Bath Indicators

Traditional bath monitoring methods focus on parameters such as pH, conductivity, or individual additive concentrations. While useful, these indicators fail to reflect the total organic load within a complex chemical system. Multiple organic species may coexist, degrade, or react during production, making selective analysis incomplete.

Total organic carbon measurement provides a unified metric that captures all dissolved organic matter regardless of chemical structure. This makes TOC particularly suitable for bonding wire coating solutions, where formulation complexity and long service life increase the risk of organic accumulation. Instead of tracking each compound individually, TOC answers a more fundamental question: how much organic contamination is present that could interfere with coating quality and bonding reliability?

High-Temperature Catalytic Oxidation for Semiconductor-Grade Accuracy

Semiconductor packaging environments demand both accuracy and robustness. High-temperature catalytic oxidation at approximately 680 °C has proven especially effective for oxidizing refractory organic compounds commonly found in coating and plating solutions.

In this approach, organic carbon is fully converted into carbon dioxide, which is then quantified using non-dispersive infrared detection. By separately measuring total carbon and inorganic carbon, precise TOC values can be calculated even in high-salt or metal-rich matrices. This oxidation mechanism is well suited to semiconductor chemicals, where lower-temperature methods may suffer from incomplete oxidation or matrix interference.

TOC Monitoring Across the Bonding Wire Process Chain

One of the strengths of TOC analysis is its flexibility across different control points in the packaging workflow.

During coating solution qualification, baseline TOC values help verify formulation consistency and supplier quality. Sudden deviations often indicate contamination during storage, transport, or raw material variation.

In ongoing production, tracking TOC trends in aging baths provides an objective basis for bath replacement or purification decisions. Rather than relying on fixed time intervals, process engineers can link bath life to actual organic load, reducing both defect risk and unnecessary chemical disposal.

Post-coating rinse and cleaning steps also benefit from TOC monitoring. Even when coating chemistry is well controlled, insufficient rinsing may leave organic residues on wire surfaces. Measuring TOC in rinse water validates cleaning efficiency and prevents contamination carryover into wire bonding equipment. In these scenarios, a stable toc analyzer functions as a real-time process safeguard rather than a passive laboratory instrument.

Recovery Testing and Data Reliability in Packaging Laboratories

Accurate TOC data must be verifiable to support process decisions. In semiconductor quality systems, spike-and-recovery experiments are widely used to confirm analytical reliability. Known quantities of organic standards are added to real coating solutions, and recovery rates are evaluated.

Consistent recovery demonstrates that matrix effects such as metal ions or high conductivity do not distort results. This validation step is especially important when TOC thresholds are directly tied to yield metrics or release criteria. It also explains why instruments designed for industrial and semiconductor use differ significantly from general-purpose water analyzers.

Automation Requirements in High-Throughput Quality Control

Packaging lines operate under tight takt times and high sampling frequency. Manual preparation increases labor cost and introduces operator-dependent variability. Automated dilution, acid addition, and gas purging reduce these risks while expanding measurable concentration ranges.

Such automation allows a single system to analyze both concentrated coating liquids and low-level rinse water without frequent method changes. For fabs running multiple coating lines, automated batch analysis significantly improves consistency and data comparability. In this context, a laboratory toc analyzer becomes an integral part of the quality infrastructure rather than a standalone testing device.

Linking TOC Trends to Yield and Reliability Outcomes

TOC data becomes far more powerful when integrated into statistical process control frameworks. By correlating organic carbon levels with pull strength variation, stitch integrity, or reliability test failures, packaging engineers can establish internal TOC control limits that reflect real production risk.

Over time, this approach transforms TOC from a reactive troubleshooting metric into a predictive indicator. Instead of responding to failures, teams can intervene earlier based on chemical cleanliness trends. For internal labs supporting packaging operations, a well-maintained lab toc analyzer supports this data-driven quality model.

Practical Considerations When Selecting TOC Equipment

Equipment selection for semiconductor packaging differs from environmental monitoring priorities. Wide concentration range, resistance to complex matrices, detector stability, and automation capabilities often matter more than ultra-low detection limits.

Modular design and consumables management reduce downtime and simplify maintenance in busy labs. Data integrity features and compatibility with quality management systems are increasingly important for global operations. While many toc analyzer manufacturers offer capable platforms, alignment with actual process chemistry and sampling volume should guide final decisions.

From Chemical Cleanliness to Packaging Reliability

As packaging technology advances toward finer pitches and more aggressive materials, chemical cleanliness has become inseparable from electrical and mechanical performance. Organic contamination in bonding wire coatings represents a subtle but powerful yield limiter that traditional inspection methods cannot detect.

By implementing structured TOC monitoring with a dedicated toc total organic carbon analyzer, semiconductor packaging teams gain quantitative control over an otherwise invisible risk factor. The result is more stable coating behavior, improved bonding consistency, and higher confidence in long-term device reliability. In modern chip packaging, TOC analysis is no longer optional; it is a foundational element of yield-focused quality control.

http://www.metashcorp.com

METASH -

AuthorPosts

- You must be logged in to reply to this topic.