- This topic is empty.

-

AuthorPosts

-

2026-01-19 at 11:19 am #6234

In modern industrial environments, precision, stability, and reliability are essential to productivity and safety. Whether in semiconductor manufacturing, precision machining, laboratory research, heavy machinery, aerospace, or civil engineering structures, vibration remains one of the most challenging issues. Uncontrolled vibration can cause equipment malfunction, reduce accuracy, accelerate wear, create noise, and even threaten structural integrity. This is where cluster vibration damping solutions play a crucial role.

By integrating advanced damping technologies and intelligent control systems, cluster vibration damping solutions help stabilize machines and structures, enhance performance, extend service life, and improve operational safety. In this comprehensive guide, we explore what cluster vibration damping is, how it works, key application areas, and why choosing a professional manufacturer such as Wuhan Glory Road Precision Technology Co., Ltd. can provide a decisive competitive advantage.

What Are Cluster Vibration Damping Solutions?

Cluster vibration damping solutions refer to a coordinated system of damping devices, isolation platforms, actuators, sensors, and control units that work together to suppress vibration across multiple points or equipment clusters. Unlike traditional single-point vibration isolators, these systems:

-

Manage multiple vibration sources simultaneously

-

Use active or semi-active control to dynamically adjust damping response

-

Offer high stability, precision, and broad frequency control

-

Improve performance in environments where accuracy and reliability are critical

These systems are especially valuable in industries where micro-level vibration can significantly affect productivity and product quality.

How Do Cluster Vibration Damping Systems Work?

Modern vibration damping systems combine mechanical engineering, electronics, and intelligent control technology. Their operation generally includes:

1. Vibration Detection

High-precision sensors detect vibration amplitude, frequency, and direction in real time. This data forms the basis of the control strategy.2. Intelligent Control and Data Processing

Control units analyze vibration data and determine the required countermeasures. Advanced algorithms adjust the damping force or isolation characteristics instantly.3. Active and Passive Suppression

Systems may include passive damping components such as rubber pads, springs, or viscoelastic materials, combined with active vibration isolation platforms, actuators, and motion controllers that generate opposing forces to neutralize vibration.4. Continuous Optimization

Through feedback loops, the system continuously optimizes its performance to maintain stability even under changing loads or environmental conditions.

Key Benefits of Cluster Vibration Damping Solutions

Implementing an advanced vibration damping solution delivers significant operational and economic advantages:

-

Enhanced Precision & Stability – Critical for semiconductor processing, optical equipment, CNC machining, and laboratory instruments.

-

Extended Equipment Life – Reduced vibration decreases component fatigue and failure risks.

-

Improved Product Quality – Stability ensures consistent manufacturing accuracy.

-

Reduced Downtime & Maintenance Costs – Less wear means fewer repairs and interruptions.

-

Improved Safety & Noise Reduction – Essential for heavy machinery and structural environments.

-

Greater Productivity & Efficiency – Stable systems operate more smoothly and reliably.

Application Fields of Cluster Vibration Damping

Cluster vibration damping technology serves a wide range of industrial and structural sectors, including:

-

Precision Manufacturing – Semiconductor fabrication, microelectronics, optics, and laser equipment.

-

Machine Tools & Industrial Automation – CNC machines, metrology systems, robotic assembly lines.

-

Scientific Research & Laboratories – Testing instruments, microscopes, and high-precision research platforms.

-

Energy & Power Generation – Turbines, compressors, generators, and rotating machinery.

-

Transportation & Aerospace – Aircraft components, test benches, and aerospace engineering systems.

-

Civil & Structural Engineering – Bridges, buildings, rail systems, and critical infrastructure requiring vibration mitigation.

Active Vibration Isolation: The Future of Advanced Damping

Traditional passive damping solutions can be effective but are limited in handling variable frequencies and complex vibration conditions. Modern industries increasingly turn to active vibration isolation systems that:

-

Use servo actuators and motion controllers

-

Respond in milliseconds

-

Provide adaptive, programmable damping performance

-

Offer superior isolation across low and high frequencies

This advanced approach represents the next evolution in vibration control technology, ensuring unmatched precision and stability.

Why Choose Wuhan Glory Road Precision Technology Co., Ltd.?

When selecting vibration damping solutions, choosing the right partner is critical. Wuhan Glory Road Precision Technology Co., Ltd. is a leading manufacturer specializing in active vibration isolation equipment. The company provides:

-

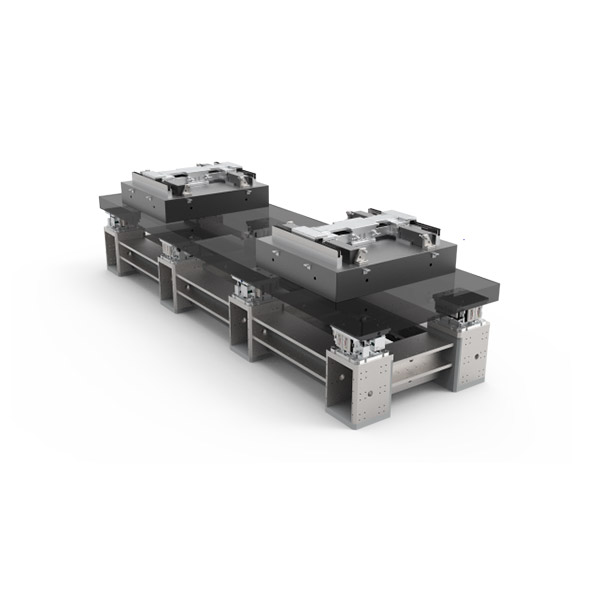

Advanced active vibration isolation platforms designed for demanding industrial and research environments

-

High-performance motion controllers and precision actuators

-

Fully integrated electromechanical systems tailored to customer applications

-

Strong engineering expertise and application support

-

Reliable quality, innovative technology, and proven international standards

Their advanced solutions deliver decisive competitive advantages, helping clients enhance performance, protect equipment, and achieve higher efficiency and precision in daily operations.

Final Thoughts

As industries move toward higher precision, automation, and intelligence, controlling vibration becomes more important than ever. Cluster vibration damping solutions provide a powerful answer to these challenges, supporting stable, efficient, and reliable operations across machinery and structural applications.

By adopting advanced technologies and partnering with experienced manufacturers such as Wuhan Glory Road Precision Technology Co., Ltd., enterprises can significantly improve productivity, extend equipment lifespan, and safeguard performance in critical environments.

http://www.glroadprecision.com

Wuhan Glory Road Precision Technology Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.