- This topic is empty.

-

AuthorPosts

-

2025-06-18 at 3:28 pm #3883

When managing large-scale electrical, construction, or automation projects, cable management isn’t just about tidiness — it’s about speed, safety, and long-term reliability. That’s where the choice between reel cable ties and standard cable ties becomes critical. Which one provides better efficiency for high-volume operations?

As a global leader in the development and manufacturing of automatic cable tie tools and accessories, Swift Automation Technology delivers cutting-edge solutions for efficient cable bundling. From nylon cable ties to fully automated cable tie machines, Swift Automation is redefining how industries approach cable management.

In this article, we explore the key differences between reel cable ties and standard ties — and which is the smarter choice for large-scale applications.

What Are Standard Cable Ties?

Standard cable ties are pre-cut, individual units made from nylon. They're widely used in virtually every industry and come in a range of sizes and tensile strengths. Most installations are done manually or with semi-automatic tools.

Pros:

-

Widely available

-

Simple to use

-

Great for small to medium projects

Cons:

-

Slower for high-volume use

-

Frequent reloading in automated tools

-

Increased labor time and fatigue

What Are Reel Cable Ties?

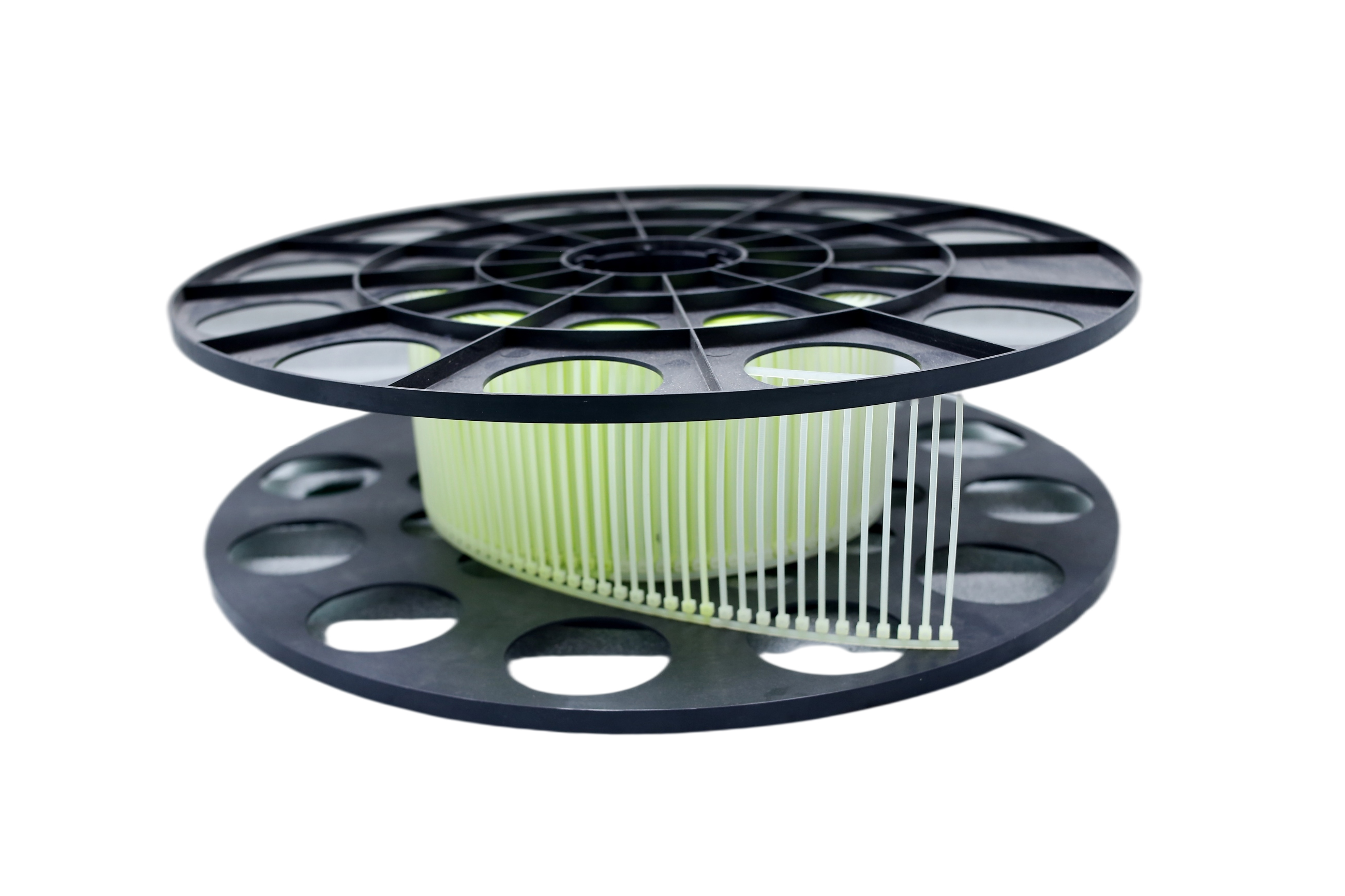

Reel cable ties are part of an automated bundling system that feeds continuous cable ties from a reel into a high-speed cable tie machine — such as the ones developed by Swift Automation Technology.

Pros:

-

Continuous bundling without manual tie loading

-

Dramatic increase in speed and productivity

-

Ideal for automated production lines

-

Reduces labor and handling costs

Cons:

-

Requires investment in automated tools

-

Initial setup may involve a learning curve

1. Speed & Productivity

Winner: Reel Cable Ties

When paired with Swift’s automatic nylon cable tie machines, reel cable ties allow operators to perform rapid-fire bundling with minimal downtime. Unlike standard ties, which need to be manually placed or loaded into a tool, reel ties allow for continuous operation — a game changer in industries like automotive, electronics assembly, and large cable harness production.

2. Cost Efficiency in Large Projects

Winner: Reel Cable Ties (for scale)

While the initial investment in an automated bundling system may be higher, the long-term savings from reduced labor and increased throughput make reel cable ties far more economical in high-volume settings. Swift Automation also provides custom automation and tool solutions to fit specific project needs.

3. Operator Fatigue and Ergonomics

Winner: Reel Cable Ties

Manual bundling with standard ties can be repetitive and physically demanding, especially over thousands of cycles. Automatic systems powered by reel cable ties significantly reduce operator fatigue, lowering the risk of injury and improving job satisfaction.

4. Consistency and Quality

Winner: Reel Cable Ties

Automation ensures consistent tension and trimming, leading to higher-quality bundling and fewer product defects. Swift Automation’s tools are engineered to deliver precise and repeatable results, ideal for quality-sensitive applications such as electronics or aerospace.

5. Flexibility and Scalability

It Depends

-

For small, one-off installations, standard ties remain cost-effective and versatile.

-

For medium to large production environments, reel cable ties paired with automated tools offer unmatched efficiency and scalability.

Why Choose Swift Automation Technology?

Swift Automation Technology stands at the forefront of innovation in cable tie automation. Our core product lines include:

-

Automatic cable tie machines and guns

-

Reel and standard nylon cable ties

-

Fully integrated bundling systems

-

Custom tooling and OEM solutions

With customers across the globe, we are trusted for durability, precision, and efficiency — helping industries scale smarter and bundle faster.

Conclusion

In the world of large-scale cable management, reel cable ties are the superior choice for speed, cost savings, and ergonomic design. While standard ties still have a place in small projects, automation with reel ties delivers a significant performance edge where it matters most.

Looking to upgrade your cable bundling process? Partner with Swift Automation Technology to integrate reel cable tie solutions that streamline your workflow and reduce your operational costs.

http://www.sz-swift.com

Shenzhen Swift Automation Technology Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.