- This topic is empty.

-

AuthorPosts

-

2025-09-08 at 2:37 pm #4743

Fork machining services play a vital role in ensuring the reliability, safety, and efficiency of forklifts, which are critical in material handling across industries. As a leading supplier, Hengli specializes in delivering high-quality fork machining solutions tailored to the demanding requirements of forklift manufacturers and users worldwide.

This ultimate guide covers everything you need to know about fork machining services, including processes, benefits, applications, and why Hengli is the right partner for your manufacturing needs.

1. What Are Fork Machining Services?

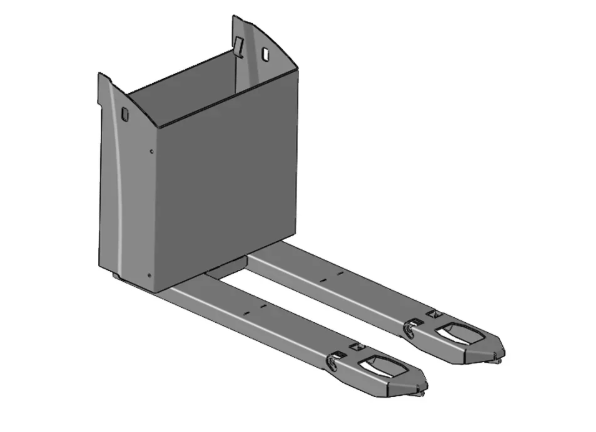

Fork machining services involve precision cutting, shaping, drilling, welding, and finishing of forklift forks— the essential load-bearing components of forklifts. These forks must meet strict dimensional tolerances and material strength standards to safely carry heavy loads in logistics, warehousing, and industrial applications.

Hengli’s fork machining services utilize state-of-the-art equipment and experienced technicians to produce forks that deliver consistent quality and long service life.

2. Why Does Quality Matter in Fork Machining?

The forklift fork endures constant stress, including heavy loads, impacts, and twisting forces. Any deviation from design specifications can lead to premature wear, safety risks, and costly downtime.

High-quality fork machining ensures:

-

Precise dimensions for perfect fit and balance

-

Robust welds and structural integrity

-

Smooth surface finishes to reduce wear

-

Compliance with industry safety standards

By choosing professional machining services like Hengli’s, businesses reduce equipment failures and maintenance costs while enhancing operational safety.

3. The Fork Machining Process at Hengli

Our fork machining process includes several critical steps to guarantee product excellence:

-

Initial Consultation: Understanding your specific requirements regarding dimensions, materials, and tolerances.

-

Material Preparation: Selecting high-strength steel plates or tubes, and cutting them accurately.

-

Precision Machining: Employing CNC milling, drilling, and turning to shape the fork precisely.

-

Welding & Assembly: Expert welding ensures strong joints and correct structural form.

-

Heat Treatment: Applying processes such as tempering to improve toughness and durability.

-

Surface Treatment: Options like powder coating or painting to protect against corrosion.

-

Quality Inspection: Rigorous testing to ensure all forks meet required specifications before shipment.

This comprehensive approach enables Hengli to support both small custom orders and large production runs efficiently.

4. Industries That Rely on Precision Fork Machining

Forks produced through precision machining serve vital roles in numerous industries, including:

-

Automotive manufacturing: Handling engines, parts, and assemblies during production.

-

Warehouse & logistics: Moving pallets, containers, and goods reliably.

-

Heavy machinery & metallurgy: Transporting steel coils, metal sheets, and heavy raw materials.

Each industry demands forks designed and machined to meet unique load and dimensional requirements, which Hengli expertly fulfills.

5. Choosing the Right Fork Machining Supplier

When selecting a supplier for fork machining services, consider the following:

-

Proven experience in forklift fork manufacturing

-

Availability of advanced CNC machinery and skilled workforce

-

Strong quality management systems and certifications

-

Ability to handle various batch sizes with consistent quality

-

Reliable delivery schedules and customer support

Hengli combines these strengths to deliver superior fork machining services worldwide.

6. Why Hengli Is Your Trusted Fork Machining Partner

At Hengli, we bring decades of expertise and cutting-edge technology to fork machining:

-

Annual production capacity of 20,000 forklift frames and components

-

Professional production lines equipped for medium and heavy steel processing

-

Comprehensive services including profile cutting, forming, welding, machining, and painting

-

Dedicated R&D and engineering teams to customize solutions

-

Commitment to quality, on-time delivery, and customer satisfaction

Our clients benefit from enhanced forklift performance, extended equipment life, and reduced maintenance costs.

7. Conclusion

Fork machining services are fundamental to the safety and efficiency of forklifts operating in demanding environments. Choosing Hengli means partnering with an industry leader focused on precision, reliability, and comprehensive support.

Whether you need custom machined forks or large-scale production, Hengli delivers solutions tailored to your exact needs. Contact us today to learn how our fork machining services can help optimize your forklift operations.

http://www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.