- This topic is empty.

-

AuthorPosts

-

2025-09-02 at 5:49 pm #4636

Cold drawn welded seamless steel pipe is the best choice for hydraulic power systems. These systems need to be very accurate, strong, and dependable. EN 10305-6 has tough rules to make sure pipes are good and exact. Makers use cold drawn seamless tube and cold drawn seamless steel pipes to get great accuracy and performance. Pipes in hydraulic systems must have:

-

Corrosion resistance to survive tough places

-

Precision to control how fluids move

-

Safety features to stop too much pressure

-

Long-lasting reliability

Cold drawn welded seamless steel pipe gives all these good things.

Key Takeaways

-

Cold drawn welded seamless steel pipes are very strong. They have exact sizes and smooth surfaces. This makes hydraulic systems safer and more dependable.

-

The cold drawing process makes pipes stronger and more accurate. Steel is pulled through dies at room temperature. This makes pipes tougher and more bendable.

-

These pipes follow strict EN 10305-6 standards. They have tight size limits, stay straight, and have strong walls. This is important for hard hydraulic jobs.

-

Special coatings and treatments keep pipes safe from rust. This helps them last up to 50 years, even in tough places.

-

Engineers use these pipes a lot in hydraulic cylinders and mobile machines. They are also used in fluid power systems. The pipes can handle high pressure and do not wear out fast.

Manufacturing Process

Cold Drawing Method

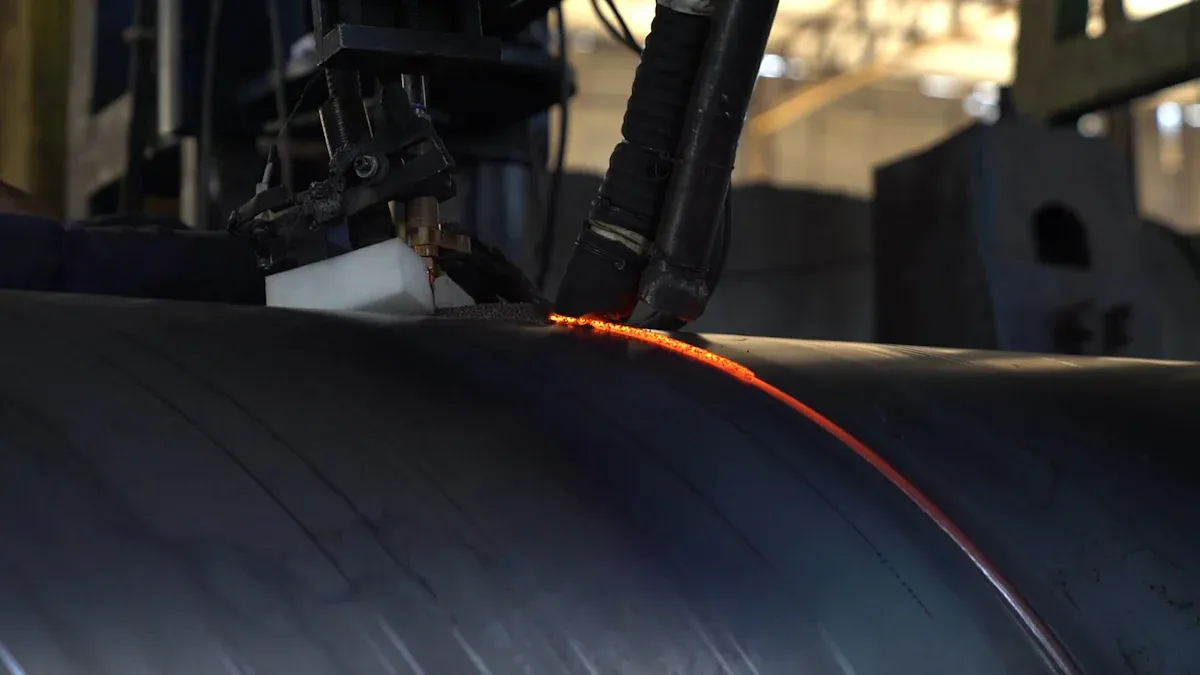

The cold drawing method shapes cold drawn seamless steel pipes. Steel is pulled through a die at room temperature. This makes the pipe stronger and harder. Makers follow several steps to get the right quality:

-

Get the raw material ready and clean it.

-

Make the tube end smaller so it fits in the die.

-

Pull the tube through the die to make it thinner.

-

Add lubrication to help reduce friction.

-

Use heat treatment like annealing to lower stress inside.

Cold drawing helps pipes have better size and surface quality. It takes away oxide layers from both the inside and outside. This gives the pipe a smooth finish. The process also changes the steel’s fiber structure. This makes the pipe stronger, tougher, and more flexible. Cold drawn seamless steel pipes made this way do not bend, crack, or break easily. This is why they work well in high-pressure hydraulic systems.

Welded Seamless Construction

Cold drawn welded seamless steel pipe has benefits from both welded and seamless ways of making pipes. The process starts with welded stainless steel tubing. This tubing is made by rolling steel sheets and welding the edges. After welding, the pipe goes through cold drawing. This step removes weak spots in the seam and makes the pipe even all around.

Aspect

Welded Pipe

Seamless Pipe

Manufacturing

Rolled and welded steel sheets

Pierced solid billet, no weld seam

Structural Integrity

Weld seam can be a weak point

Homogeneous wall, stronger and more durable

Strength

Lower maximum pressure rating

Corrosion Resistance

Weld seam may be vulnerable

Advantage due to absence of weld seam

Dimensional Accuracy

Less consistent wall thickness

Tighter tolerances and uniform thickness

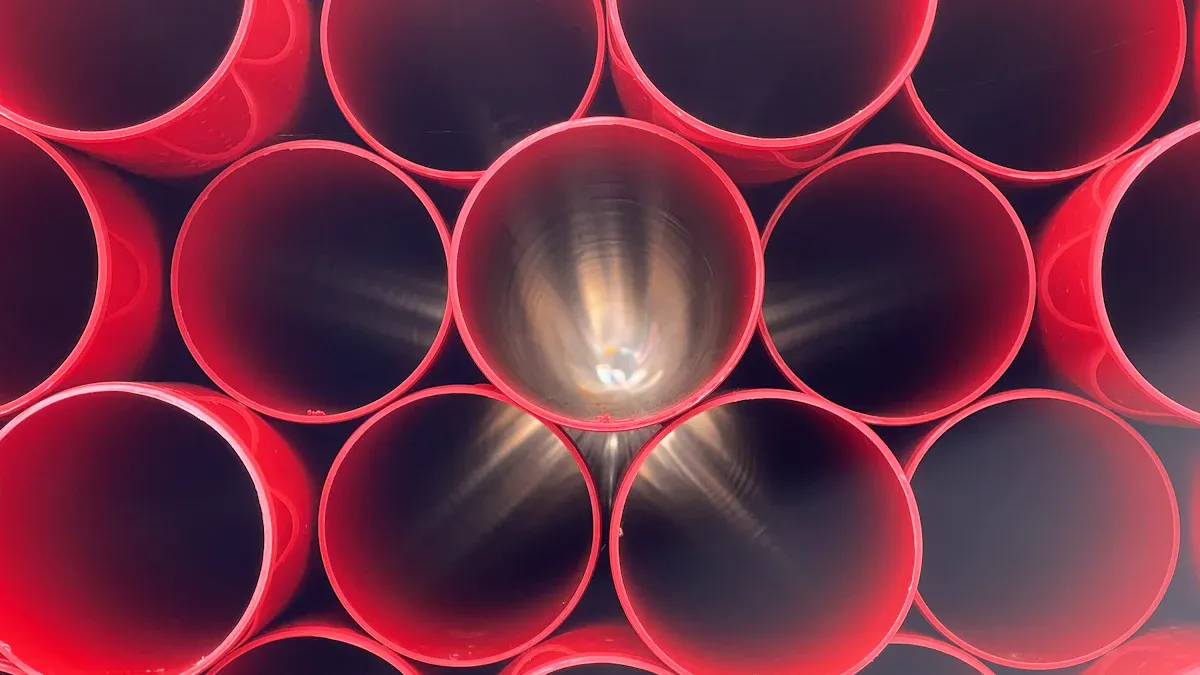

Cold drawn seamless tube made from welded stainless steel tubing is very reliable. The seamless structure gives the pipe extra strength and long life. This is very important for hydraulic power systems.

EN 10305-6 Standards

EN 10305-6 has strict rules for cold drawn seamless steel pipes. These rules set tight limits for outside and inside diameters, straightness, and wall thickness. For example, outside diameter can only change by ±0.08 mm for small tubes and ±0.35 mm for bigger ones. The pipe must stay straight, with only a small bend allowed. Over any 1 meter, the bend cannot be more than 3 mm.

Makers of smls steel pipe follow these rules to make sure every cold drawn seamless steel pipe works well for hydraulic uses. They check quality with mechanical and chemical tests. They also use non-destructive testing and look closely at welds and the pipe’s surface. These steps make sure welded stainless steel tubing and smls steel pipe are strong, exact, and dependable for important fluid power systems.

Key Benefits

High Dimensional Accuracy

Cold drawn seamless steel pipes are very exact in size. This is important for hydraulic power systems. The cold drawing process pulls steel through dies at room temperature. This makes pipes with even wall thickness and almost no mistakes. These pipes can be made with tolerances as close as ±0.05 mm. This is much better than hot rolled or regular welded pipes. The table below shows how different pipe types compare in size accuracy:

Pipe Type

Dimensional Accuracy

Tolerance

Surface Roughness (Ra)

Application Notes

Cold Drawn Seamless Pipe

High

±0.05 mm

≤ 1.6 μm

Used in high precision fields, uniform thickness

Hot Rolled Seamless Pipe

Lower

Larger

Rougher

Less precise, uneven wall thickness

-

AuthorPosts

- You must be logged in to reply to this topic.